Decoding the Secrets of Cylinder Deactivation

In the ever-evolving world of automotive engineering, one technology stands out for its ingenious approach to improving fuel efficiency without sacrificing performance: cylinder deactivation. This innovative system, also known as variable displacement, has been quietly revolutionizing the way our engines operate, offering a solution to the age-old dilemma of power versus economy. But what exactly is cylinder deactivation, and how does it manage to squeeze more miles out of every gallon while still delivering the punch we crave when we hit the accelerator?

A Historical Perspective

The concept of cylinder deactivation isn’t new – it dates back to the early 20th century. However, early attempts were plagued by rough operation and reliability issues. It wasn’t until the advent of sophisticated engine management systems and electronic controls in the 1980s that cylinder deactivation began to show real promise. Cadillac was among the first to introduce a modern version in 1981, but it was short-lived due to technical challenges.

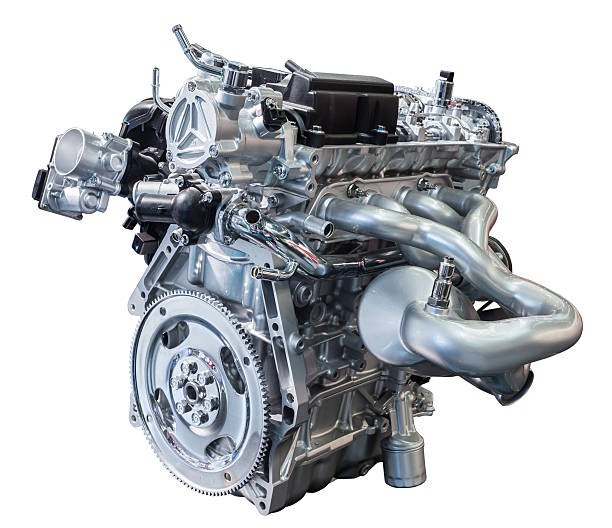

The Mechanics Behind the Magic

Modern cylinder deactivation systems are marvels of engineering precision. When the engine control unit determines that full power isn’t needed, it deactivates specific cylinders by keeping their intake and exhaust valves closed. This prevents air and fuel from entering these cylinders, effectively turning them into air springs. The pistons continue to move up and down, but no combustion occurs in the deactivated cylinders.

Seamless Transitions

One of the most impressive aspects of cylinder deactivation is how imperceptible it is to the driver. Advanced algorithms and sophisticated hydraulic systems ensure that the transition between full engine operation and partial cylinder use is smooth and undetectable. This seamless operation is crucial for driver acceptance and the overall success of the technology.

Beyond Fuel Savings

While improved fuel economy is the primary benefit of cylinder deactivation, it’s not the only advantage. This technology also contributes to reduced emissions, as less fuel burned means fewer pollutants released into the atmosphere. Additionally, by reducing the workload on certain engine components, cylinder deactivation can potentially extend engine life and reduce wear and tear.

Challenges and Solutions

Despite its benefits, implementing cylinder deactivation isn’t without challenges. Engineers must carefully balance factors such as vibration, noise, and thermal management to ensure optimal performance. Advanced materials and sophisticated software algorithms have been key in overcoming these hurdles, allowing for wider adoption across various vehicle types and engine configurations.

The Future of Cylinder Deactivation

As automotive technology continues to advance, so too does cylinder deactivation. The next frontier involves more dynamic systems that can deactivate any cylinder at any time, rather than fixed sets of cylinders. This flexibility promises even greater efficiency gains and opens up new possibilities for engine design and optimization.

Impact on Performance Cars

Contrary to what some enthusiasts might fear, cylinder deactivation isn’t just for economy-minded vehicles. High-performance cars are also benefiting from this technology, allowing for powerful engines that can still achieve respectable fuel economy when not being pushed to their limits. This dual-nature capability is particularly appealing in a world increasingly focused on efficiency without wanting to sacrifice the thrill of driving.

Consumer Perception and Adoption

Despite its technical merits, cylinder deactivation has faced some skepticism from consumers. Concerns about reliability and performance have lingered, partly due to early implementations that were less refined. However, as the technology has matured and its benefits have become more apparent, consumer acceptance has grown. Education and firsthand experience have been key in demonstrating that modern cylinder deactivation systems can deliver efficiency without compromise.

The Role in a Changing Automotive Landscape

As the automotive industry navigates a shift towards electrification, one might wonder about the relevance of technologies like cylinder deactivation. However, experts predict that internal combustion engines will continue to play a significant role for years to come, especially in hybrid powertrains. In this context, cylinder deactivation remains a valuable tool in the quest for maximizing efficiency and reducing emissions across a broad range of vehicles.

In conclusion, cylinder deactivation represents a triumph of automotive engineering, offering a clever solution to the perennial challenge of balancing power and efficiency. As this technology continues to evolve, it promises to play a crucial role in shaping the future of internal combustion engines, proving that there’s still plenty of innovation left in the world of pistons and valves. For drivers and enthusiasts alike, cylinder deactivation offers the enticing prospect of having our cake and eating it too – power when we want it, efficiency when we need it, all at the push of a pedal.